Safety First: Trailer brakes are responsible for ensuring that both your vehicle and the attached trailer come to a complete stop. Without functional brakes, stopping can become unpredictable, especially when carrying heavy loads, which may result in dangerous situations on the road.

Legal Compliance: In Australia, maintaining working trailer brakes is mandatory under road safety regulations. Trailer brake requirements vary based on the Gross Trailer Mass (GTM) of your trailer, and failure to comply can result in fines or defect notices.

Prolonging the Lifespan of Your Trailer: Regular maintenance of trailer brakes not only ensures safety but also extends the life of your braking system and prevents costly repairs in the future.

TIP: Consider investing in a trailer brake kit to ensure all components are properly addressed, providing you with the peace of mind that your entire braking system is up to standard.

There are different types of trailer brakes, and each requires specific maintenance procedures to ensure they remain effective:

Electric brakes are commonly used in trailers and are controlled by an electric brake controller installed in the towing vehicle. These brakes provide smooth and efficient stopping power and are a legal requirement in Australia for trailers over 750kg GTM.

Hydraulic brakes operate using fluid pressure. When the towing vehicle applies the brakes, the pressure in the hydraulic system increases, which activates the trailer brakes.

Override brakes are used in lighter trailers up to 2000Kg. These brakes operate when the trailer pushes against the towing vehicle during deceleration, automatically activating the brakes.

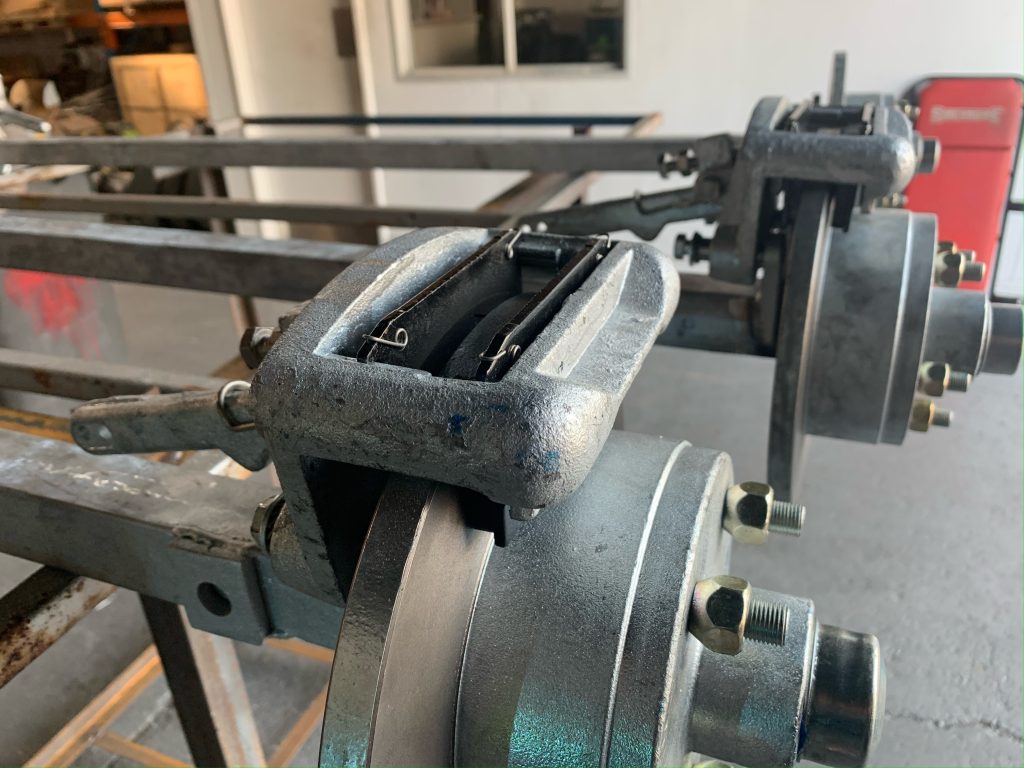

Trailer brakes come in two main varieties: disc brakes and drum brakes. Disc brakes are typically more powerful and provide quicker stopping power, while drum brakes are more common in trailers and easier to maintain.

If you’re looking to ensure your trailer’s braking system is in top shape, purchasing a trailer brake kit is a smart investment. A trailer brake kit addresses all components of the brake system in one package, ensuring that you have everything needed for a proper installation or replacement. These kits often include brake pads, rotors, callipers, and other essential components, making it easier to maintain or upgrade your system.

Benefits of a Trailer Brake Kit:

Whether you’re upgrading your current system or replacing worn-out parts, investing in a trailer brake kit ensures you’re addressing the whole brake system, which is key to maintaining optimal safety and performance.

Regular inspections can help prevent brake failure. Look for the following warning signs that your trailer brakes need attention:

Perform a thorough visual inspection of the brake components. Check for worn-out brake pads, damaged rotors, and leaks in hydraulic lines.

Before every trip, test the trailer’s braking system. If you have electric brakes, use the brake controller in your vehicle to manually activate the trailer brakes and ensure they respond properly.

Measure the thickness of the brake pads. If they are less than the manufacturer’s minimum thickness recommendation, they need to be replaced.

If your trailer uses hydraulic brakes, inspect the brake fluid lines for any leaks. Low brake fluid can reduce the effectiveness of the system.

For mechanical or overrun brakes, ensure the brake shoes are correctly adjusted. Misadjusted brakes can lead to uneven wear and decreased braking performance.

To keep your trailer brakes in top working condition, follow these maintenance tips:

Set up a maintenance schedule to inspect your trailer brakes regularly, especially before long trips. Ideally, you should check the brakes every 5,000 km or annually, whichever comes first.

Worn brake pads and damaged rotors can significantly reduce braking power. Replace them as needed to maintain optimal stopping power.

Ensure that all moving parts in the brake system are well-lubricated. This helps reduce friction and prevents wear and tear on the brake components.

If you have a hydraulic braking system, regularly check the brake fluid levels. Top it up when necessary and flush the system according to the manufacturer’s recommendations.

For electric brakes, check the wiring and ensure all connections are secure. Damaged or loose wiring can affect brake performance.

In Australia, the regulations for trailer brakes are enforced under the Australian Design Rules (ADRs) and the Vehicle Standards Bulletin 1 (VSB1) Version 6 or the Latest update for trailers with a Gross Trailer Mass (GTM) of 4.5 tonnes or less. These rules specify when brakes are required based on trailer weight:

Failure to adhere to these regulations can result in penalties, vehicle defect notices, or being pulled off the road by authorities.

Trailer brakes are essential for both safety and legal compliance in Australia. Regular inspection and maintenance will ensure your trailer brakes function correctly, preventing accidents and saving you from expensive repairs down the road. Always check your trailer brakes before towing, and follow the maintenance tips mentioned above to stay safe on the road.

For more detailed information on trailer regulations, visit the Australian Government’s Vehicle Standards website.

and we also offer multiple shipping options.